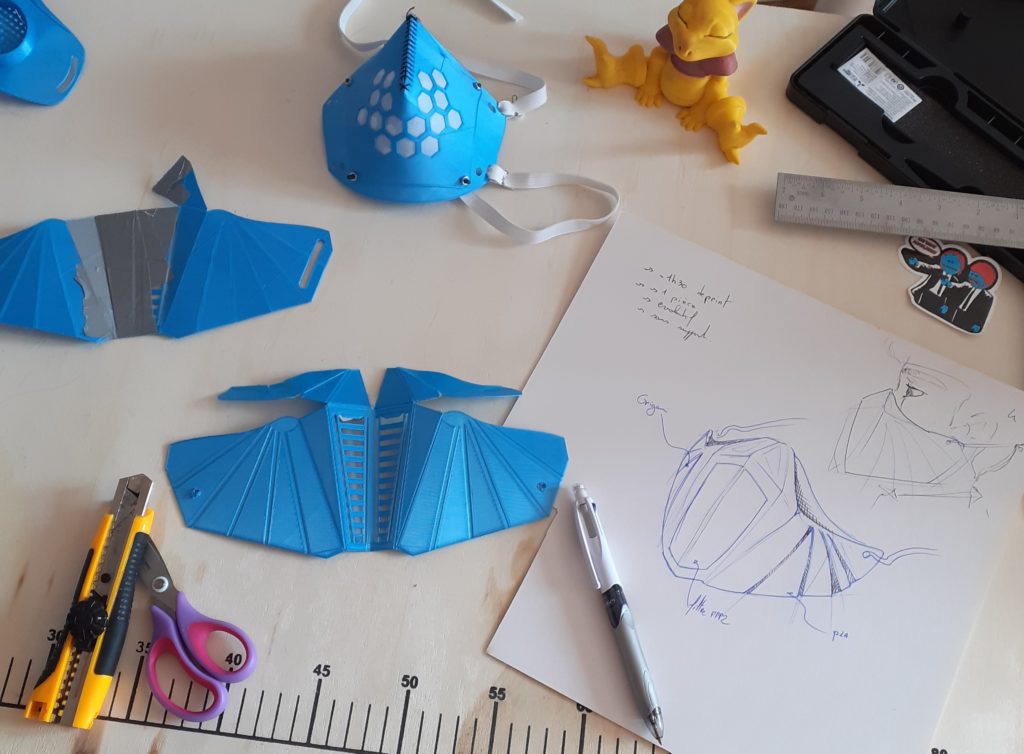

After having printed various 3D models (.STL) of PPE available on the internet, I was challenged by the manufacturing time. A TableTop FDM machine can hardly print more than 2 masks per day. On average, it takes 6 hours to print one model, however it took about 10 hours to print the ‘most difficult’ one.

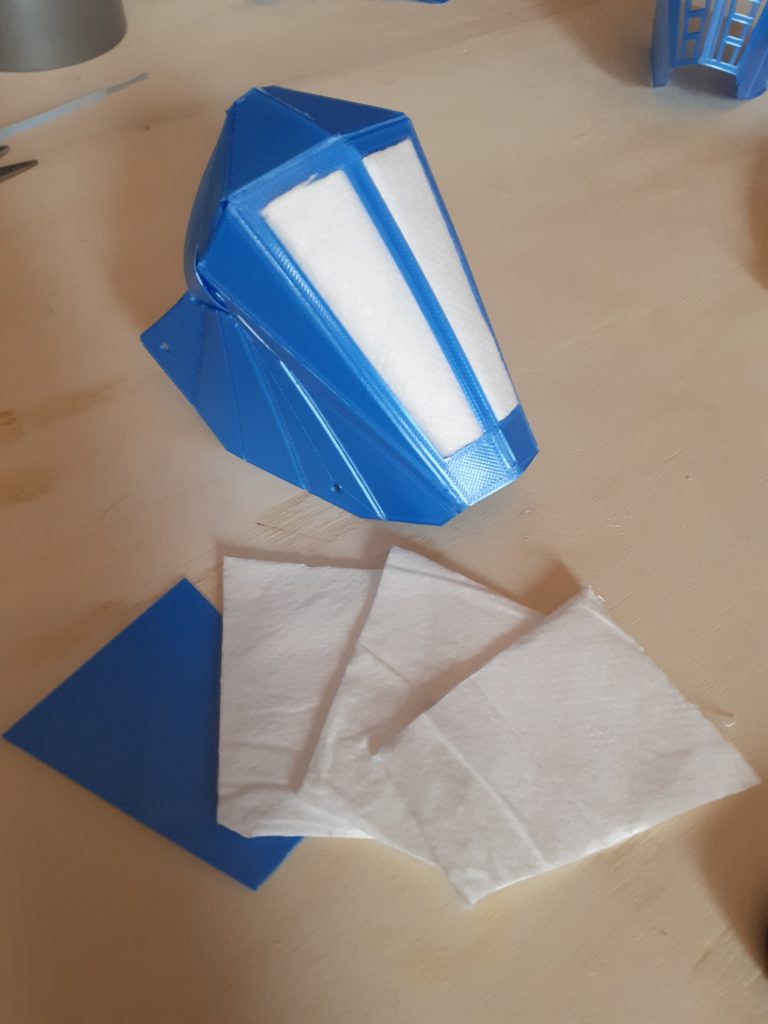

Once the masks are printed, the only thing left to do is add the filter. But where to find it? Is adding fabric enough? Do I need to find a substitute? So many unanswered questions… That’s why I looked at the problematic from another angle…

The question was: how can we extend or optimise the lifespan of a FFP2-3 mask?

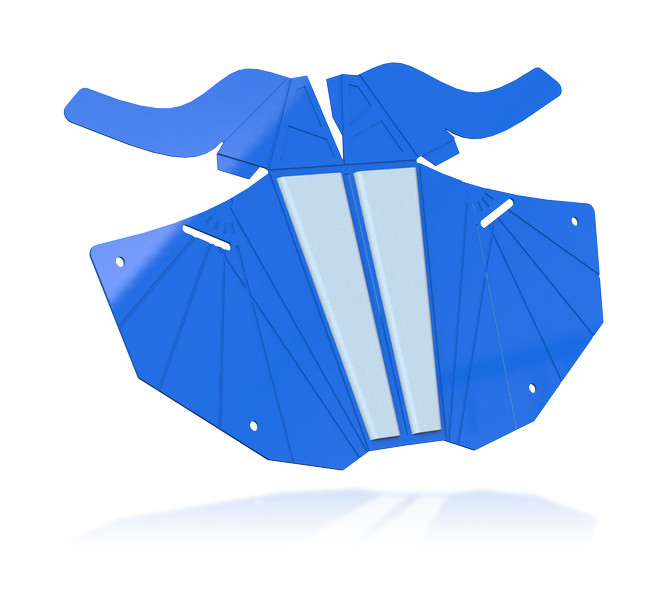

After looking into different possibilities, I thought about a mask with a compartment on the front to be filled with a filter cut into a FFP2 mask, keeping in mind that a FFP2 mask can be divided in 4 pieces of equal size.

Thanks to this simple process, I was able to extend the lifespan of a mask to four times as long!